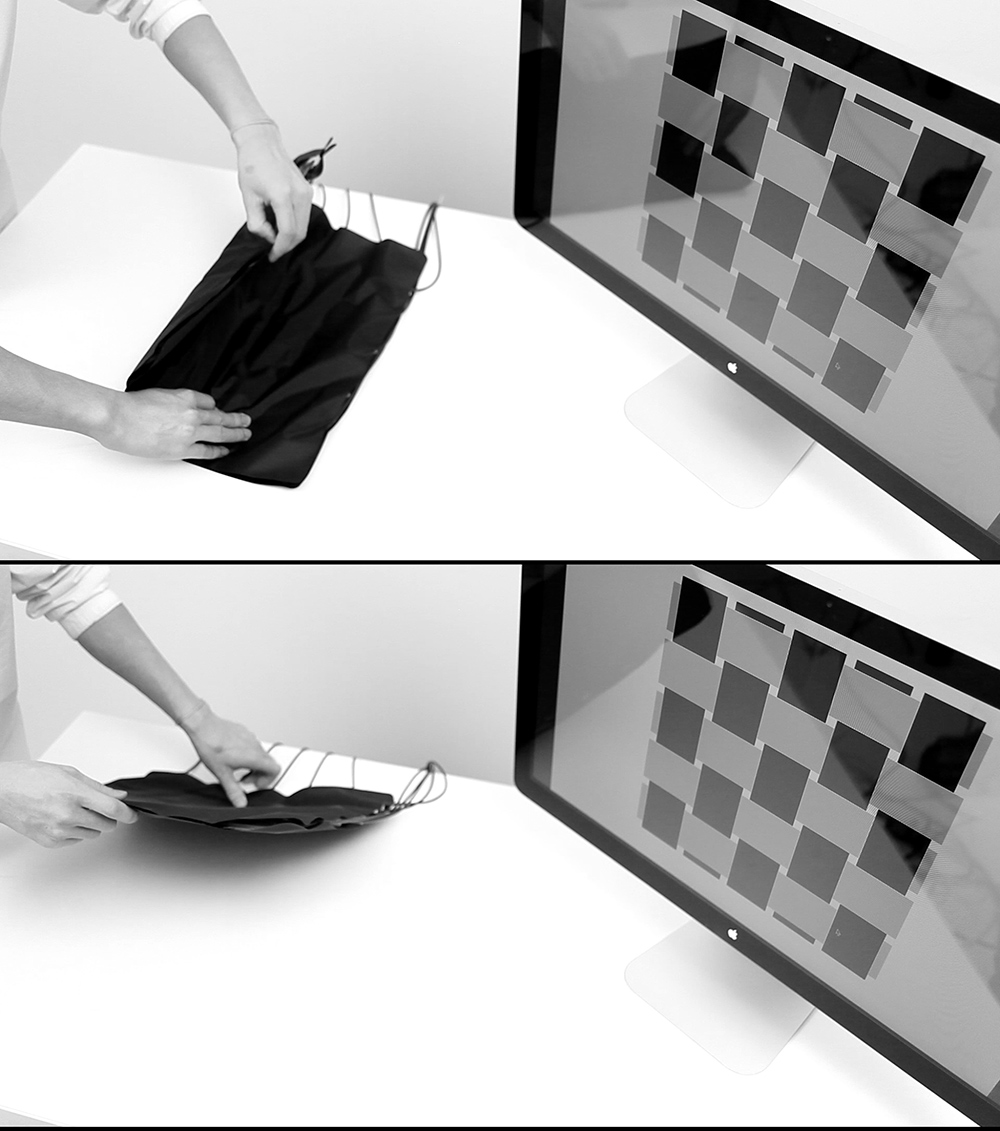

The basic layer jamming system is composed of an airtight envelope with multiple thin layers of “flaps” (e.g., paper) inside. The system utilizes negative air pressure to vacuum-pack the thin layers of material to amplify the friction between each layer. The higher the vacuum pressure (negative pressure), the bigger the friction between each layer. If we consider the entire envelope as one material system, the global behavior is stiffness changing.