Several alternative material deposition processes are available for SDM. Embedded electronic devices are built up with polyurethanes, to form the housings, and sacrificial wax which is removed by melting. Polyurethanes are deposited as 2 part resin/activator mixtures, while the wax is deposited with a hot-glue gun. The parts are built on pallets which are transferred from station to station using robotic automation.

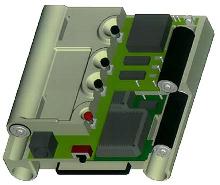

Frogman is a three layer polyurethane structure, which was manufactured as one underwater computer built up in layers of polyurethane.

In order to connect to a heads up display, a commercially available vulcanized underwater connector (i.e. mating plug can be connected/disconnected underwater) is used. Since polyurethane will not bond to rubber, a polyurehane clamp with an internal O-ring is first bonded around the cable connection from the connector to the PCB. Tape is also placed on the connector face to protect it from subsequent deposition. The connector is then placed on a polyurethane layer and embedded in the next layer. In operation, water which penetrates between polyurethane/rubber interface is stopped at the embedded clamp.

Last updated on 19 July 1997