Pascaline Assembly Instructions

General Advice

- Check your parts collection. Make sure you're not missing any parts;

you don't want to discover this at the last moment.

- Apply Loctite to all screws unless the instructions say not to. Don't coat

the entire screw, just the section where the nut will end up.

- Make sure parts in the laser cutter are cut all the way through before moving them.

- When in doubt, consult the CAD model.

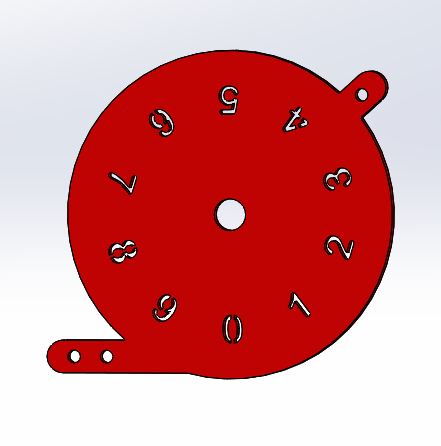

Readouts

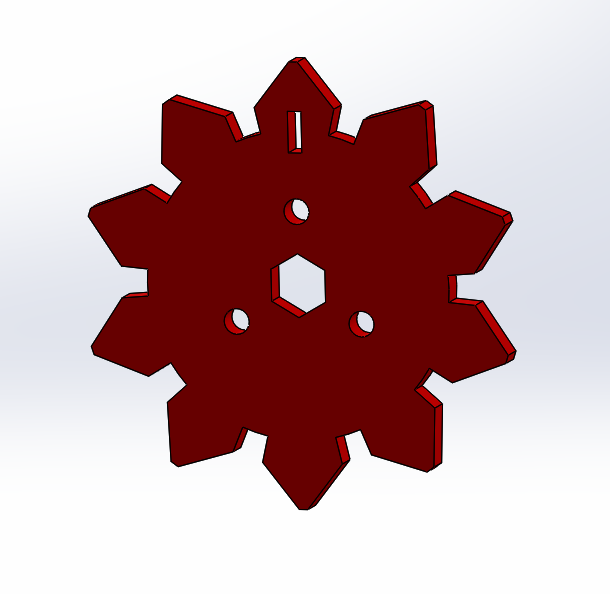

- Insert three 1 1/2 inch screws into a red ReadoutGear and

lay it face down on the table.

- Add a 1/4 inch spacer to each screw.

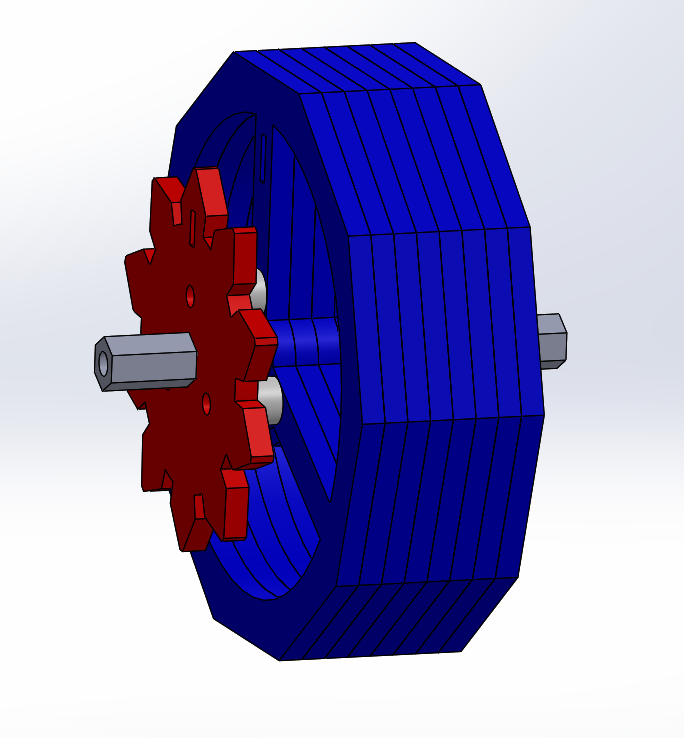

- Add a ten-sided blue ReadoutCylinder piece, making sure that the

rectangular slot in the strut lines up with the rectangular slot in

the red ReadoutGear.

- Add seven more blue ReadoutCylinder pieces, for a total of eight,

making sure that all the rectangular slots line up.

- Gently pick up the assembly and place the fingers of one hand on the

three screw heads to keep them from slipping out. With your other

hand, apply Loctite to the ends of the screws.

- Add nuts but don't tighten them yet.

- Slide a 2.5 inch hex standoff through the center of the assembly and

make sure that it moves freely.

- With the shaft still in place, tighten the nuts with screwdriver

and pliers and make sure the assembly still slides freely.

- Repeat the above steps two more times to construct two more readout

assemblies.

Accumulators

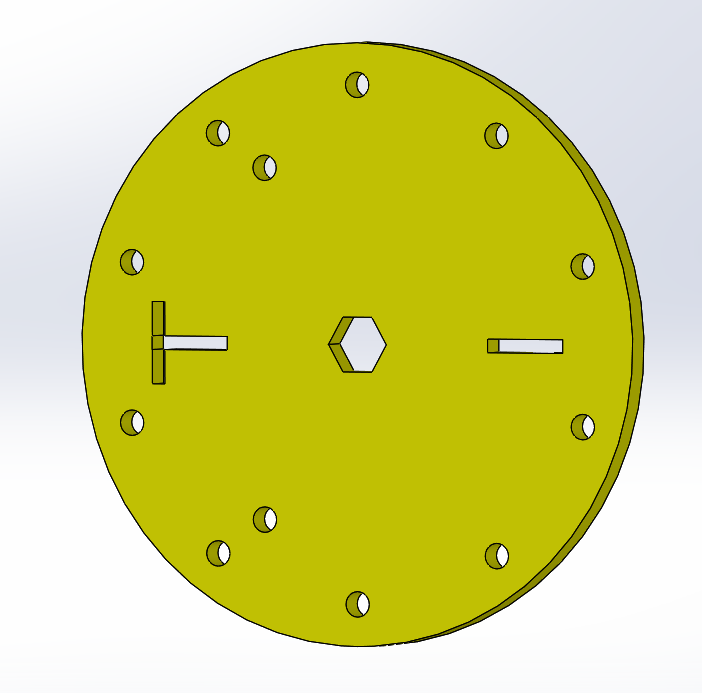

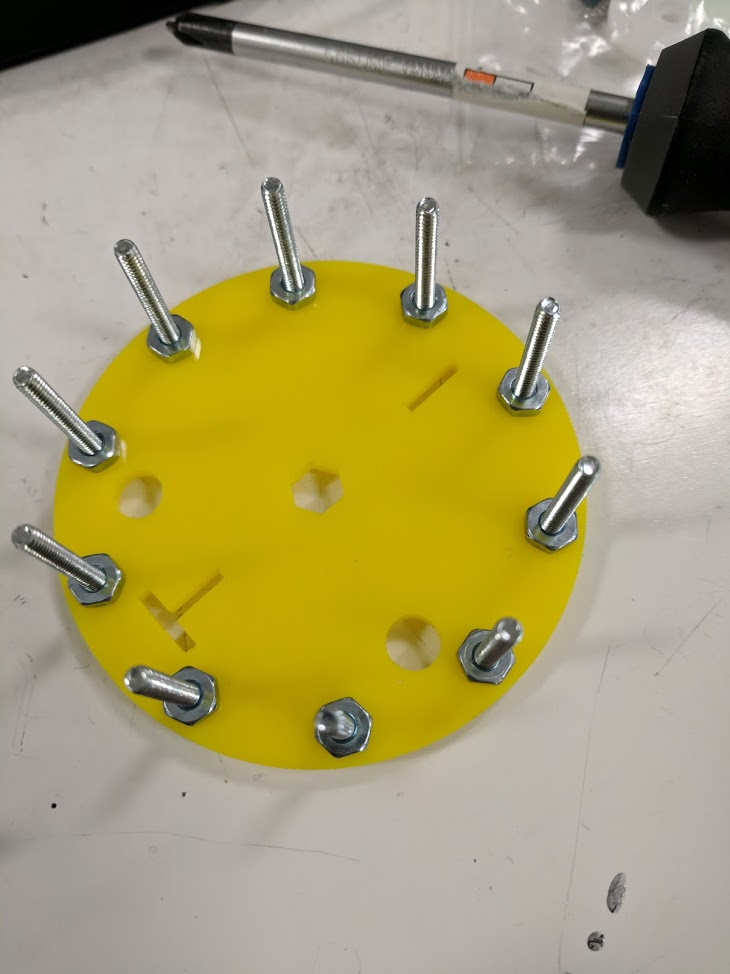

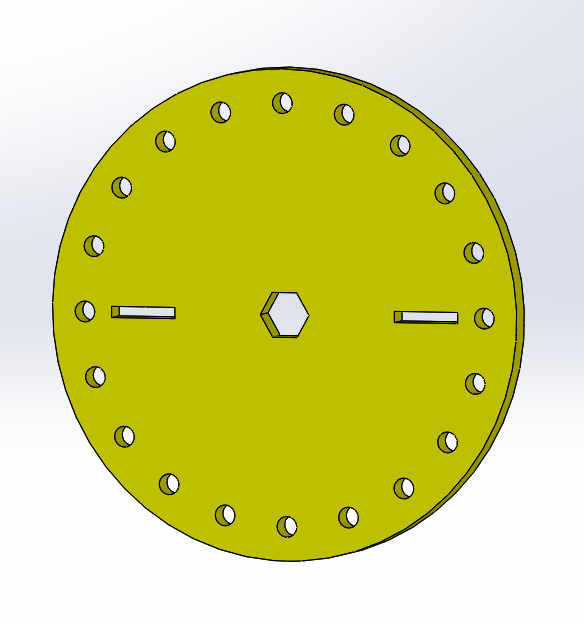

- Select an accumulator gear with the T-shaped slot in it. (Six

gears have these slots, and three don't have them.)

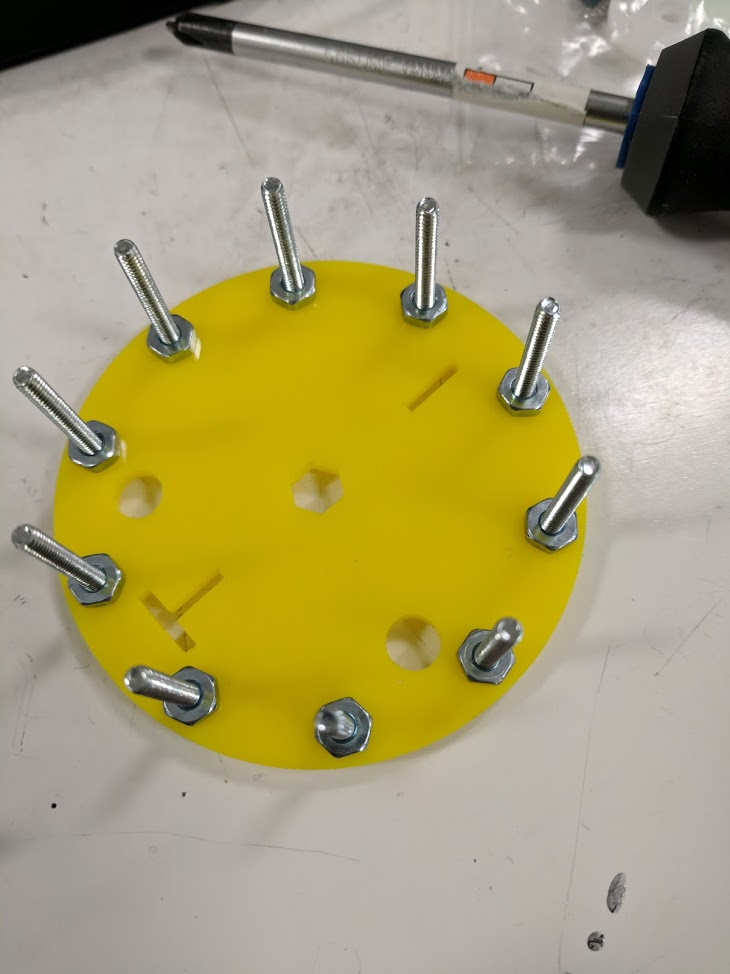

- Insert ten 1 inch screws into the ten outer holes in the gear,

and fasten them with nuts and Loctite.

- Repeat the process to produce a second accumulator gear.

- Join the pair of accumulator gears back-to-back using two 1 inch round standoffs

and four 1/4 inch screws.

- Insert ten 1/2 inch screws into the ten outer holes in a green OutputGear,

and fasten them with nuts and Loctite.

- Attach a yellow OutputGearCap to the green OutputGear on the same

side as the 1/2 inch screws, using two 3/8 inch screws, nuts, and

Loctite. All 12 screw heads should be on the same side of the green

OutputGear.

- Attach the output gear and endcap assembly to the end of a 5 inch standoff (we don't have a 5 inch standoff, so connect a male-to-female 1 inch standoff stead)

using a 1/4 inch screw and Loctite.

- Repeat the above instructions two more times to build the remaining

two accumulators.

Input units

- Insert twenty 1 inch screws into an AccumulatorGear in the

input2 configuration (without the T-slot; there should

be three such gears) and secure them with nuts and Loctite.

- Insert a 2 inch hex standoff into each AccumulatorGear and

temporarily secure both ends with a washer and 1/4 inch screw; don't

use an Loctite at this pont. We won't add the InputWheels to these

shafts until we're ready to assemble the top panel.

Backstops

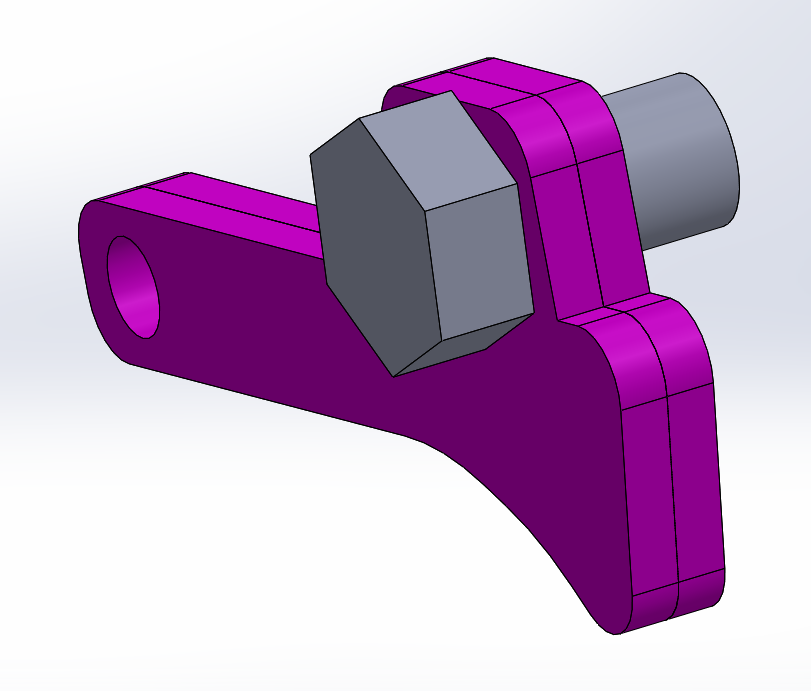

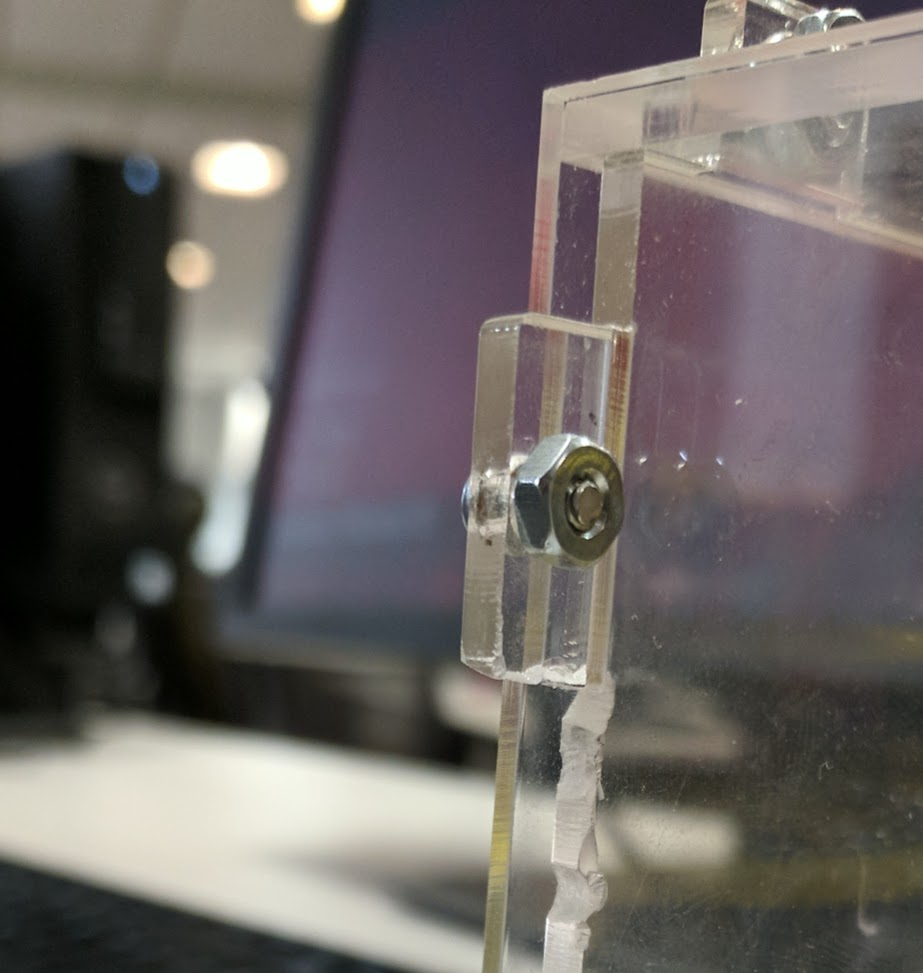

- Put a 5/8 inch bolt through a pair of BackstopPawl large holes, with the screw facing in the direction seen in the diagram below.

- Add a dab of Loctite and a 3/8 inch nut (the large, heavy nut) and tighten.

- Repeat the above instructions two more times to build the remaining two backstops.

Top panel

- Attach a red InputBacking piece to the TopPanel using a 3/8 inch

screw and nut. Leave the nut loose.

- Put two 3/4 inch screws though a FingerStop piece and add two 1/4 plastic

inch spacers. Then carefully pick up the FingerStop and attach it to

the TopPanel and InputBacking using two nuts. Finally, tighten all

nuts.

- Repeat the above instructions two more times for the remaining two

digit positions.

- Attach the yellow ReadoutShield to the underside of the TopPanel using two 3/8 inch

screws.

- Attach the blue ReadoutCover to the top side of the TopPanel using two 5/8 inch

screws coming up from the bottom and two lock nuts on the top. Tighten the locknuts

just enough to hold the ReadoutCover firmly but still allow it to move.

- Attach two 1 inch hex standoffs to the TopPanel, in the holes that are in between the

input wheels, using 1/4 inch screws.

- Attach the yellow InputBrace to the standoffs using two more 1/4 inch screws.

- Remove the washers from the top end of an Input assembly shaft, and slide the shaft up through

the InputBrace and TopPanel.

- Slide a red InputWheel between the top of the TopPanel and the

underside of a FingerStop; then push the Input shaft through the hole

in the InputWheel. The tiny "0" digit cut in the InputWheel should

line up with one of the slots in the yellow AccumulatorGear below it

on the shaft.

- Secure the shaft with the washer and 1/4 inch screw removed earlier.

- Repeat the above steps two more times to install the remaining Input assemblies.

Sautoirs

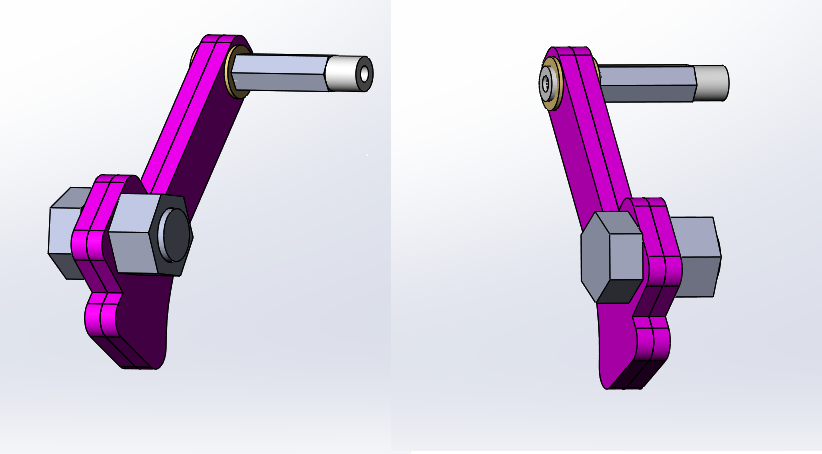

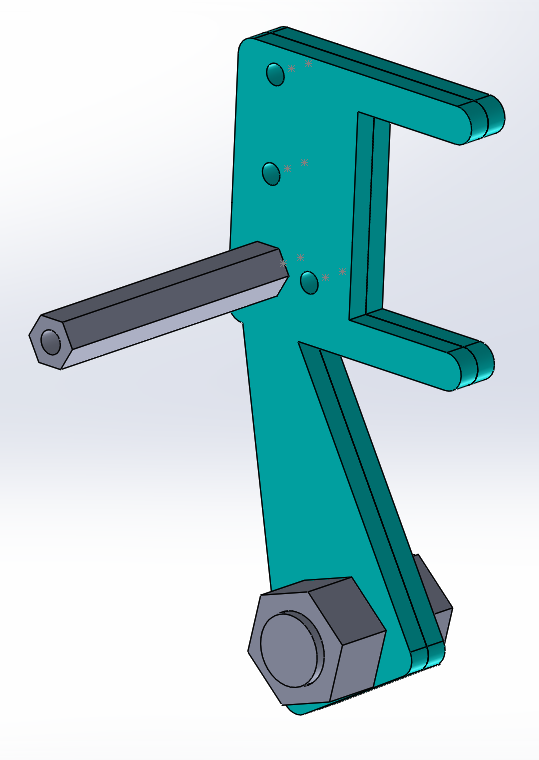

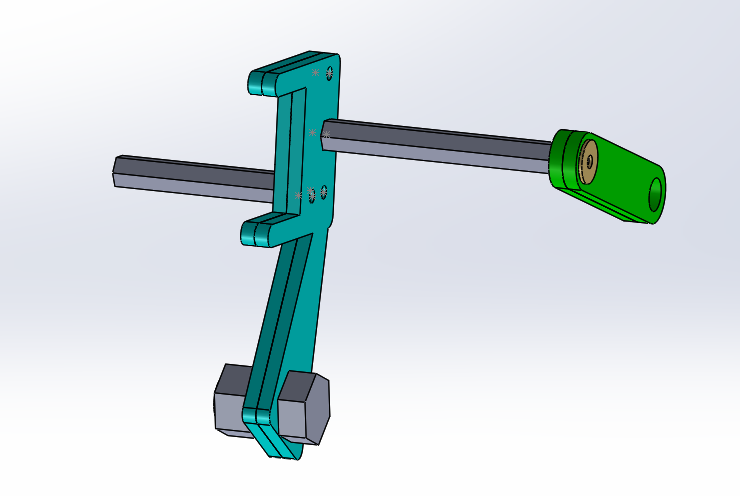

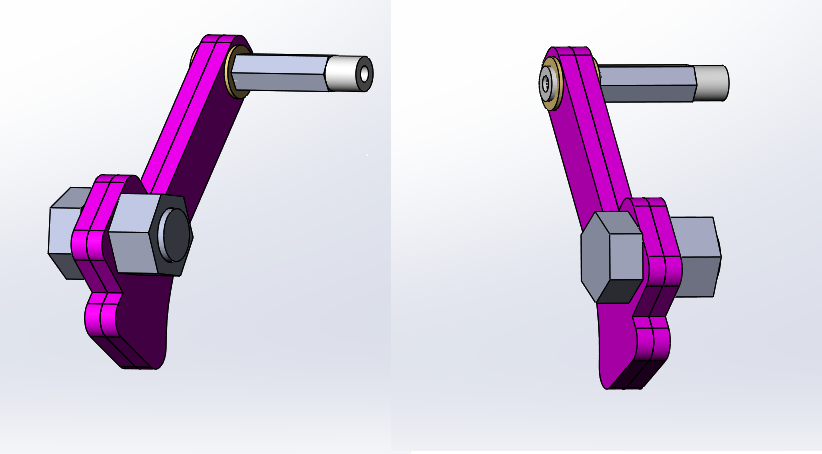

- Hold the carry lever pieces so they look like a capital F. One will have a hex hole below the other (CarryLeverB). Fit the 1.5 inch standoff into the hex hole. Line the other carrylever (CarryLeverA) up opposite the standoff, and secure with a 3/8 inch screw so the two carry lever pieces fit perfectly.

-

Feed a 5/8 inch bolt screw through the large hole. Loctite and tighten the 3/8 inch nut. The result should look like the picture below.

- Turn around the sautoir and insert a 2 1/2 inch hex standoff into the hex hole on the other side of the carry levers. Run a 3/8 inch screw through the opposing hole to secure the standoff.

-

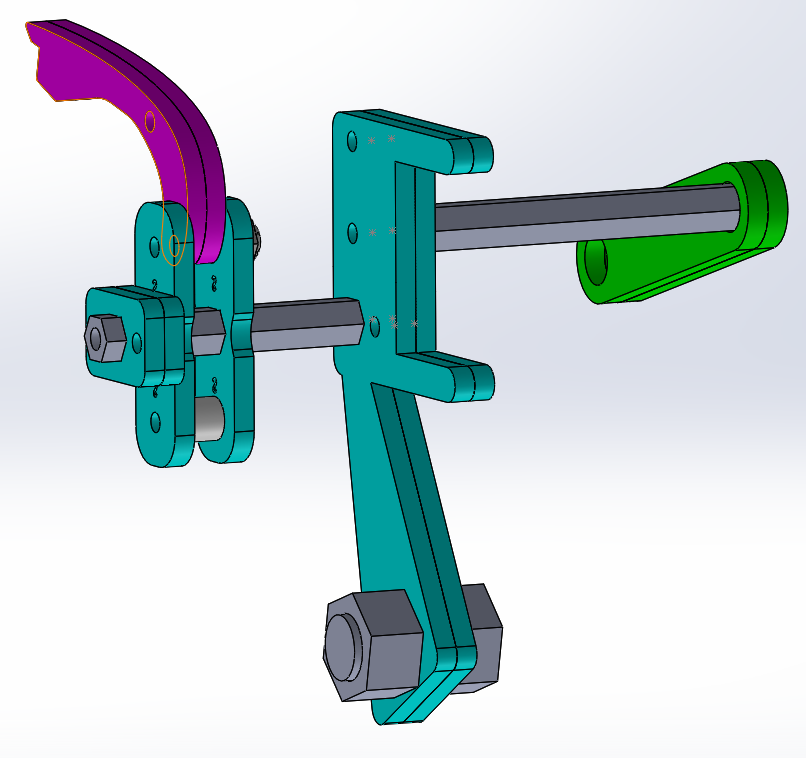

At the other end of the 2 1/2 inch hex spacer, place two of the SautoirMountC4 arms. Cap the end of the hex standoff with a washer and 3/8 inch screw to hold these pieces onto the standoff. Its that the SautoirArmC4's slide down the standoff for now, they'll be secured later. Your assembly should now look like this

- Join two SautoirArm pieces with a 5/8 inch screw through the top hole, separating them with a 1/4 inch spacer. Don't tighten the nut down yet.

- Insert two CarryPawl pieces between the SautoirArm pieces, and connect them with a 3/4 inch screw through the bottom hole. Use a locknut instead of a regular nut on the front face of the assembly, but don't tighten it down.

- Thread the SautoirArm Assembly onto the 1.5 inch standoff. Tighten the regular nut fully. Tighten the locknut until the CarryPawl no longer swings freely, then loosen it a bit until the CarryPawl swings freely again. At this point, your Sautoir assembly should look similar to this (excluding small nuts and screws):

- Thread two SautoirMountC2 pieces onto the standoff. Your Sautoir should now look similar to this (excluding small nuts and screws):

- Slide configuration SautoirMountB (the one with the hex hole) onto the end of the standoff, then line up the other Sautoir mount (SautoirMountA). Secure the two mounts with a 3/8 inch screw through the center holes onto the 1.5 inch hex standoff.

Your assembly should look similar to this (excluding small nuts and screws):

- Insert a 3/4 inch screw into the rightmost small hole in the SautoirMount such that the screw exits the SautoirMountC2 pieces roughly above the small hole in the CarryPawls. Insert a 3/8 inch screw (going in towards the SautoirMount) into the CarryPawls. Thread a spring on this screw and attach the spring to the 1 inch screw above it. Your spring setup should look similar to this:

- Repeat the above instructions to construct the second sautoir.

Ratchets

- Lay out the BottomPanel on the table so that the engraved "Pascaline" label is legible facing up in the top left corner.

- Examine the MidPanel2; there are three long tabs on the bottom edge, and three short tabs on the top edge.

- Temporarily drop MidPanel2 into the third slot of the BottomPanel; it will only fit one way. This assures that you've found the front side of the panel. The three small holes for the backstop pawls should be located above and to the left of the larger holes for their respective accumulator and output shafts.

- Install three 3/4 inch standoffs into the top holes of MidPanel2, on the front side, using 1/4 inch screws and washers.

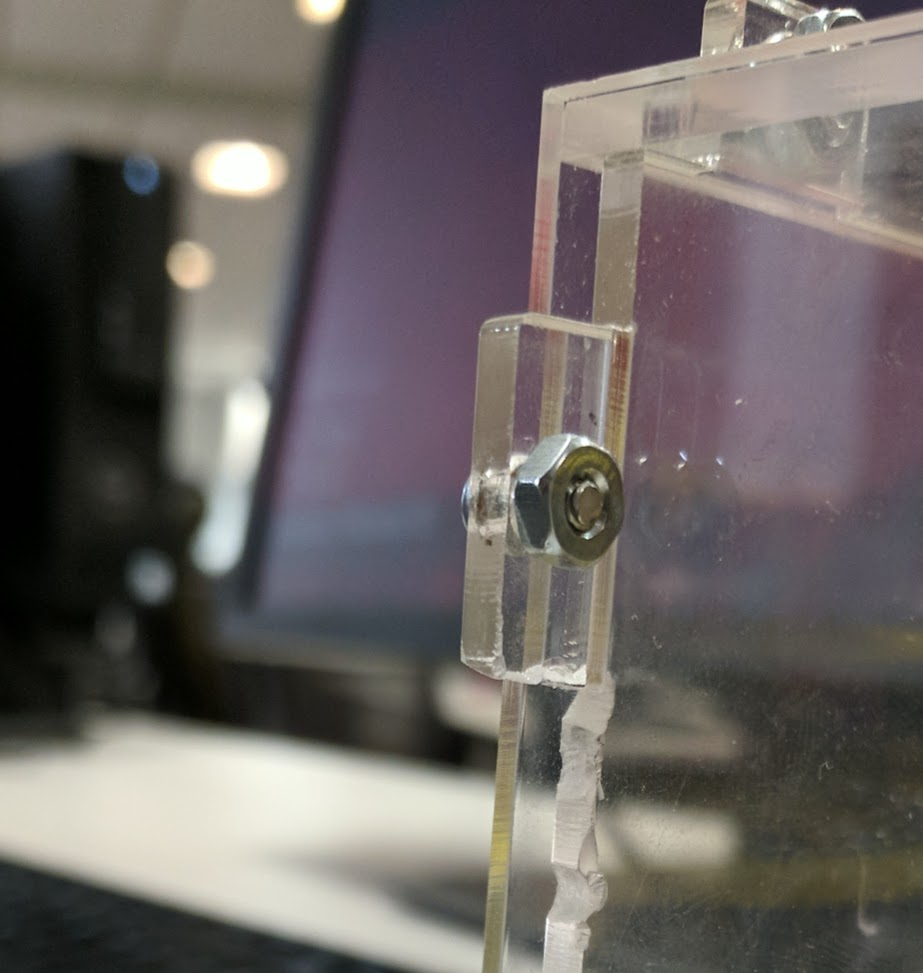

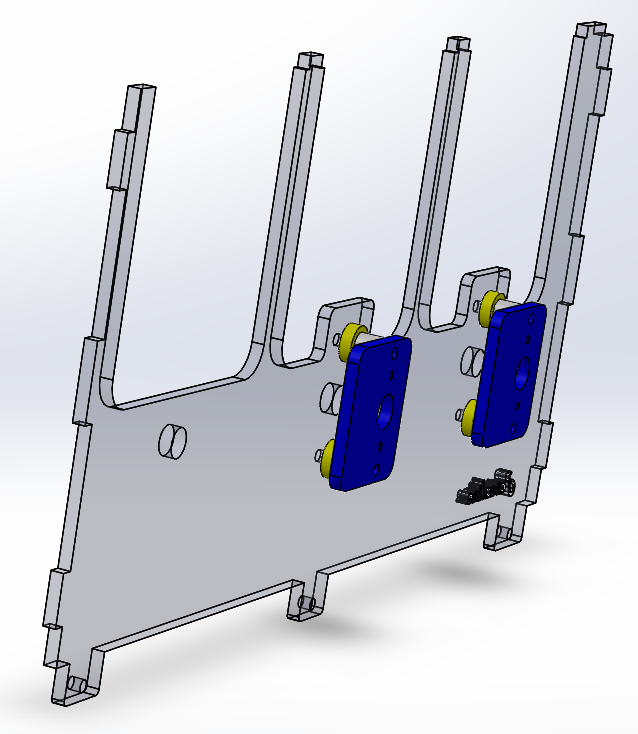

- Install the two blue SautoirBacking panels on the front side of the MidPanel2 using 1/4 inch plastic spacers and 5/8 inch screws, and nuts.

MidPanel1 Assembly

- Lay out the BottomPanel on the table so that the engraved "Pascaline" label is legible facing up in the top left corner.

- Examine the MidPanel1; there are three long tabs on the bottom edge, and four short tabs on the top edge.

- Temporarily drop MidPanel1 into the third slot of the BottomPanel; it will only fit one way (the pascaline engraving should be on the same side as the pascaline engraving on the bottom). This assures that you've found the front side of the panel.

- Install the two blue SautoirBacking panels on the back side of the MidPanel1 (the side facing the sautoirs) using 1/4 inch plastic spacers, a SautoirFrontSpacer, 3/4 inch screws, and nuts. Your assembly should now look like this.

Final Assembly

- Drop the MidPanel2 into the third row of the BottomPanel.

- Slide the sautoirs into position such that each corresponds to the location seen in the diagram below. The big hole in the SautoirArm should line up with the hole in MidPanel2 and in the blue SautoirBacking plate.

- Make sure your spacers are inserted onto the accumulator shaft according to the following diagram (as viewed from below):

- Insert an Accumulator shaft into the leftmost hole in MidPanel2, through the sautoir and the SautoirBacking pate, and a little bit beyond.

- Rotate the accumulator's OutputGear until the two rectangular slots are vertical. Then pick up an AccumulatorGear assembly, rotate it so that the T-slots are at the top (the vertical slot of the T-slot should be aligned with the vetical slot in the OutputGear), and thread it onto the accumulator shaft. You will have to press down the CarryPawl in order to get the AccumulatorGear assembly all the way onto the shaft. The CarryPawl should be resting outside the circle of screws in the AccumulatorGear. This should allow you to rotate the AccumulatorGear on the shaft, and the spring-loaded CarryPawl will click as it passes each screw.

- Insert MidPanel1 assembly into the second row of the BottomPanel.

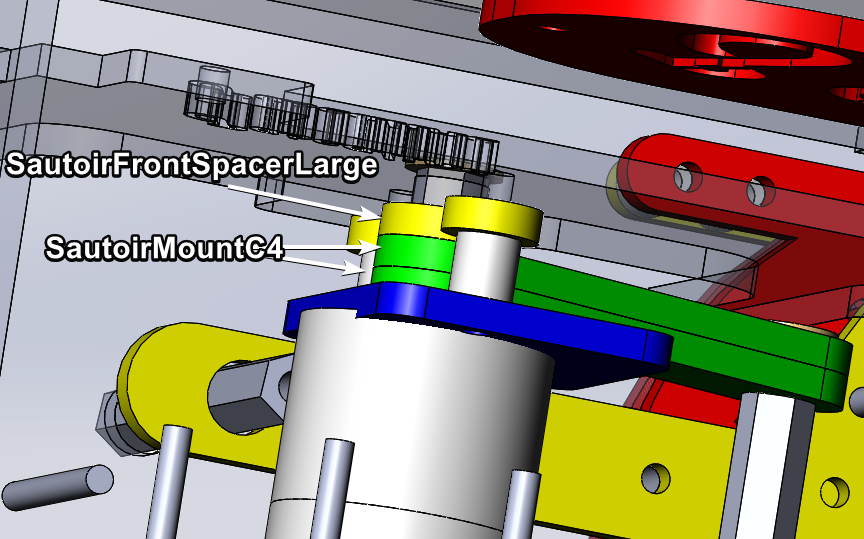

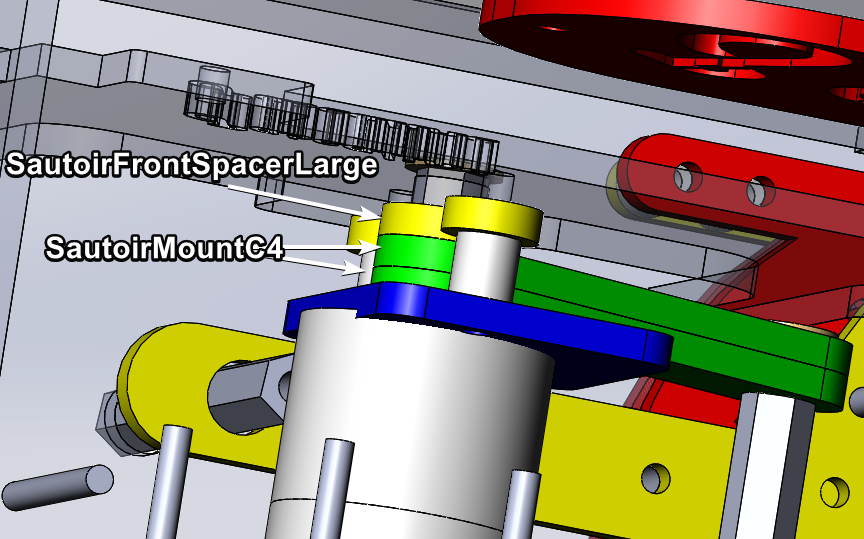

- Put the three accumulator shafts first through the SautoirBackingPlate attached to MidPanel1, then the two SautoirMountC4s, then through SautoirFrontSpacerLarge, and finally through the large hole in MidPanel1.

Your attachment to MidPanel1 should look like this:

- Put a 1/4 inch screw through a washer and use it to fasten an accumulator shaft in place in relation to MidPanel1. Repeat for the other two shafts.

- Examine the BackPanel. There are three long tabs on

the bottom edge, and two long tabs with a short tab between them on

the top edge. Drop the BackPanel into the slot in the BottomPanel

furthest from you.

- Rotate an accumulator assembly until the T-slot in the yellow

AccumulatorGears is at the top. Note that one of the slots in the

green OutputGear is also vertical and aligned with the T-slot.

- Drop a blue Readout assembly in place between MidPanel2 and the BackPanel, rotated so that the slots in the red ReadoutGear and the blue ReadoutCylinders are pointing straight up, aligned with the green OutputGear. Insert a 2.5 inch standoff through MidPanel2 to hold the Readout assembly in place and slide two yellow plastic spacers on the standoff between the ReadoutCylinder and BackPanel. Push the standoff through BackPanel and fasten it with a washer and 1/4 inch screw at each end.

- Repeat the above steps two more times to install the remaining

two Readout assemblies.

- Insert a 1/4 inch plastic spacer into a hole in a backstop.

Using a 3/8 inch screw, screw through a washer, through the spacer in

the backstop, through another washer, and into a 3/4 inch hex

standoff. Attach the 3/4 inch hex standoff to MidPanel2 by screwing a

3/8 inch screw through MidPanel2, into the 3/4 inch hex standoff.

- Repeat the above step two more times to install the remaining backstops.

- Place an adhesive sticker on every face of the three ReadoutCylinders:

30 stickers total.

- The face directly above the rectangular slot in the

ReadoutCylinder should be labeled with a black "8", with a red "1"

above it. The face to the right of it should be labeled with a black

"9" and a red "0" above it. Continue all the way around the circle.

- Examine the two SidePanels. Notice that there are four columns of slots, but only

one of those columns has four slots; the rest have three slots. The BackPanel is the

only panel with four tabs; the MidPanels have three tabs. Install the two SidePanels.

- Fasten the SidePanels using 1/4 inch screws and nuts through the

holes in the BackPanel tabs.

- Drop the FrontPanel into the first slot in the BottomPanel but do

not add any screws yet. Move the SidePanels outwards so that they

don't engage the FrontPanel. Tilt the FrontPanel forward but leave it

resting in the BottomPanel.

- Rotate the three accumulators so that the output cylinders all

read "9". (Make sure it's the regular "9", not the twos-complement

"9".)

- Rotate the three input wheels so that the "9" is just to the right

of the finger stop.

- Drop the topPanel into position, resting on the top slots in the

BackPanel and MidPanels. Tilt the FrontPanel back so that its slots

also fit through the TopPanel.

- Slide the SidePanels into position so they mesh with all the side

slots.

- Verify that the Input assemblies are lined up properly by dialing

in an input and watching the numbers change. When a position goes

from "9" to "0" a carry should occur. If the alignment is off, lift

up the TopPanel, turn the InputWheel to the correct position, and put

the TopPanel back down again.

- When the alignment is correct, secure the SidePanels with 1/4 inch

screws through the holes in the FrontPanel tabs.

- Complete the assembly by adding 1/4 inch screws to the vertical

tabs extending below the BottomPanel and above the TopPanel.

|