In 1995, I was fortunate to win the opportunity to enter a selective international cooperative graduate program, in which students are given the chance to work in Mektron, one of the largest electronics corporations in Japan. The gold plating technique of Mektron's main product Flexible Printed Circuits (FPC) is the most advanced in the world, and their multi-layered FPC, mainly used in compact camera, notebook and mobile phone, controls over 50% of the world market. I studied the automatic assembly lines there, and was deeply impressed by their advanced technology and management.

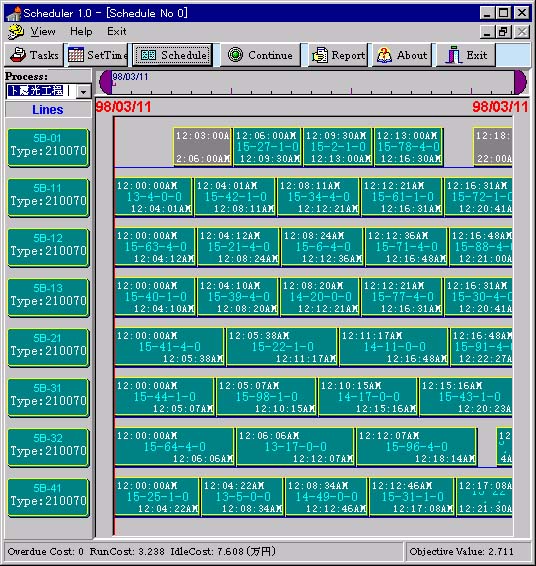

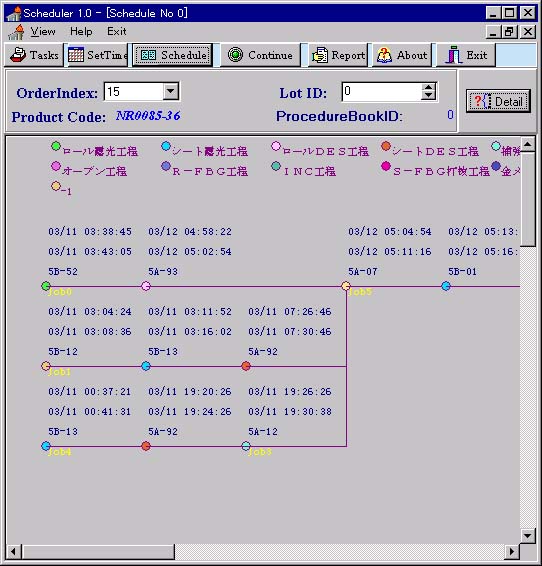

I joined a team to develop a new Management Information System (MIS) for Mektron's Kashima factory. My duty is to devise and implement the production scheduling algorithm, and to build and maintain part of the enterprise's production management DB based on my scheduling module. This is no easy job: There are many different products in the company, each of which has a highly complex and re-entrant fabrication flow with precedence restraints between jobs, i.e., a job cannot be processed until some other jobs (predecessors) are finished; Also, when consecutive operations on the same production line require different molds, setup times are introduced, which, in our case, are operation-sequence-dependent; To make things even more complex, different operations can be processed on different subsets of assembly lines while the lines are not identical. The scheduling objective is to improve on-time-shipment percentage and to minimize production lead time and cost. Uncertainties in the manufacturing environment, such as unforeseen machine breakdowns, delayed preparation of raw materials, order cancellations, rush order arrival and increased order priorities, proposed other difficulties. This task is a real challenge to me.

During the summer of 1995, I read over a lot of English papers and textbooks on scheduling and resource allocation, among them are Muth, J. F. et al. (1963) Industrial Scheduling, and French, S. (1982) Sequencing And Scheduling. They helped me formulate and acquire a profound understanding of the problem. At the same time, I explored many optimization methods, such as branch-and-bound method with heuristic branch selection rule, pseudo-polynomial dynamic programming algorithm, Lagrangian relaxation approach, GA (Genetic Algorithms) and TABU Search, trying to find the most appropriate one to solve the problem. After many efforts and failures, I finally devised a framework, which consists of a GA-based prescheduling module and a policies-based real-time rescheduling module, to address those complex scheduling constraints. The framework proved to be effective during our later implementation and is now on its way to practical use. I have three English papers published to summarize the work I did.

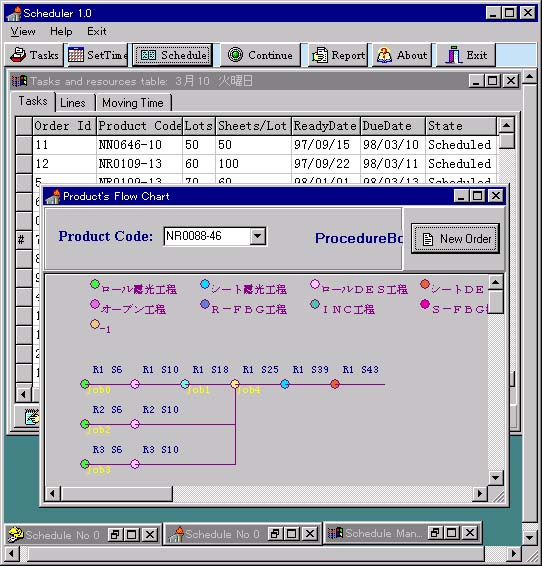

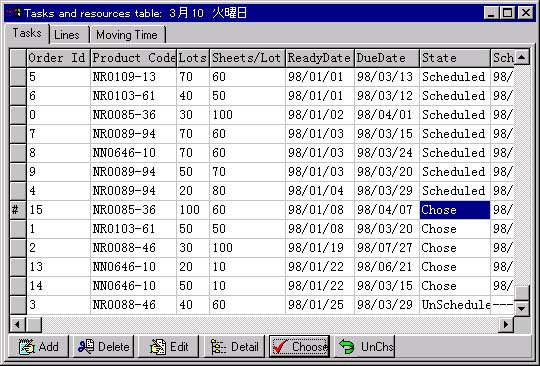

From October 1996, I began my full-time work to implement the scheduling module under the client/server architecture. Integration of management information into the system became yet another challenge: we had to figure out how to implement the logical database design that works for both the senior managers and line operators, how to keep data integrity in a distributed system, and how to share data among heterogeneous databases (DB2 and MS SQL). Working day in and day out not only led to a phase solution, but also provided me with up-to-date computer skills and precious experience of involvement in the management of a manufacturing enterprise. Nearly 26,000 lines of source code in Delphi and C++ in my module witnessed my every single step to success. I cherished this one busy year which benefited me so much in my preparation for a career in the modern industry.

Title: The Research and Development of a Flexible Printed Circuits Production Scheduling System

Abstract:

With many prominent properties, Flexible Printed Circuits (FPC) are in booming market demands. However, developing a FPC production scheduling system has been plagued with difficulties of the design of both an effective core scheduling algorithm and a friendly C/S platform that implements the algorithm. Due to its inherently complex constraints and objective, together with a dynamically changing job-shop environment, the FPC production scheduling system covers nearly all the difficulties existing in the electronics manufacturing scheduling, the research of which has both theoretical and industrial importance.Firstly in this thesis, a framework is proposed for the FPC scheduling system, which is designed as a static pre-scheduling algorithm at each specified time point combined with dynamic re-scheduling during production process. The second part of the thesis introduces the implementation of the above framework in the largest FPC manufacturer in the world. The implemented system adopts a C/S architecture, in which object-oriented and distributed relationship database technologies have been used. At the end of the thesis, corresponding conclusions are drawn and future directions of research are suggested.

Key words: Flexible Printed Circuit(FPC); Production Scheduling System; Genetic Algorithms; Job-shop Scheduling; Database Application

Papoose Scheduler Snapshots: