Publications

[1] J. F. Alfaro, L. Weiss, P. G. Campbell, M. C. Miller, C. Heyward, J. S. Doctor and G. Fedder, BioImplantable Bone

Stress Sensor, in Proceedings of the 2005 IEEE Engineering in Medicine and Biology 27th Annual Conference (EMBS '05), September

1-4, 2005, Shanghai, China.

[2] P. Basset, J. F. Alfaro, D. Novosel, A. de la Plaza, D. Stancil and G. Fedder, "Chip-Size" Antennas for

Implantable

Sensors and Smart Dust, in The 13th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS

'05),

pp. 457-460, June 5-9, 2005, Seoul, Korea.

[3] J. F. Alfaro and G. Fedder, Actuation for Probe-Based Mass Data Storage, in Technical Proceedings of the Fifth

International Conference on Modeling and Simulation of Microsystems (MSM '02), pp. 202-205, April 22-25, 2002, San Juan, Puerto Rico.

[4] R. Carley, R. T. El-Sayed, D. F. Guillou, J. F. Alfaro, G. Fedder, S. Schlosser, D. Nagle, G. Ganger and J. Bain,

MEMS memory elements, in Proceedings of the 2001 Non-Volatile Memory Technology Symposium (NVMTS '01), pp. 1-5, November 7-8,

2001,

San Diego CA.

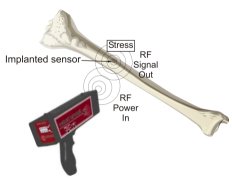

Implantable, Telemetry-Based MEMS Bone Sensor

Goals:

&bull Develop an implantable bone sensor to detect in vitro bone stress via wireless RF interface.

&bull Leverage MEMS technology

&bull Chip size is minimally invasive

&bull Optimize integration with bone tissue

Target Specifications:

&bull <= 2 mm by 2 mm area

&bull Biocompatible

&bull Wireless interface for power/data transmission

&bull Pressure range from1 kPa to 10 kPa

Applications:

&bull Real time status of bone health through minimally invasive surgery.

&bull Implantable sensors and drug delivery systems.

Examples:

Implantable strain gage sensors to monitor bonegrowth (e.g., for grafting procedures, facture healing), or

Measure bone loss (e.g., in osteoporosis) over time to customize dosage of therapeutic drugs.

CMOS Remote Integrated Sensing Platform (CRISP)

Create a reusable modular design for monolithic wireless sensors with applications in:

&bull Biomedical monitoring

&bull Distributed sensors for industrial and transportation systems

&bull Implantable sensors

Attack issues inhibiting complete integration

&bull Wireless communication of sensor data

&bull Wireless dc power generation

&bull Co-design of the sensor/electronics interface

&bull Perform initial fabrication and testing

One unique feature of this research is development of an on-chip antenna system, as opposed to an external antenna. We expect there

will be difficulties in co-design of the wireless system and the sensor system, which will extend our existing work on MEMS CAD.

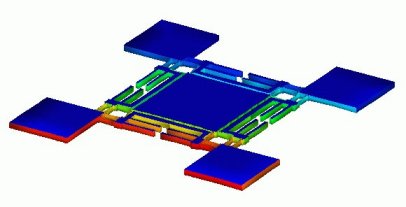

Micro Media Actuation for Probe-Based Mass Data Storage

With MEMS based data read/write systems we envision a full computer on a chip device given the miniaturization scale of all its

components. It is also possible to achieve faster data access (~ 100 ms), which may improve overall data caching in computers. Most

of these systems introduce a translational media actuator since the rotational disk has latency.

Given these factors it is possible to visualize a media actuator with a stroke of +- 50 um in both lateral directions x-y for a MEMS

storage system. The swept area is set according to the area of the tip actuator that will read/write the data from the media.

My work has been focused in the development of the micro media actuator (MMA) for the system. The research covers the following

aspects:

&bull Design specifications and analysis of the MMA, the choice of micro mechanical topology and the required geometry.

&bull Use of an optimization tool to obtain a better understanding of the system, definition of an objective function plus

constraints

chosen for the current generation of the MMA.

&bull Process flow implemented to fabricate the MMA.

&bull Results obtained from the mechanical, electrical and coupled electromechanical system simulations.

&bull Experimental results obtained during the processing and final test of prototype MMA

The overall group project is focused on the following technology areas:

&bull CMOS-MEMS design and processing of an array of tip-actuators

&bull Deep-reactive ion etch (DRIE) process ing of a chip-scale media actuator.

&bull Processing compatible with CMOS-MEMS to allow integration of magnetic read-write heads with micromechanical

actuators.

&bull CMOS control electronics needed for s table tip actuation.

Demonstration of the magnetic probe writing and reading process.

The objective of this project is to create and demonstrate the feasibility of MEMS technology for a rewritable data storage cache

capable of recording densities greater than 10 GB/cm2, utilizing an array of CMOS micromachined tip actuators, a single MEMS-based

media actuator, and perpendicular magnetic probe recording technology.